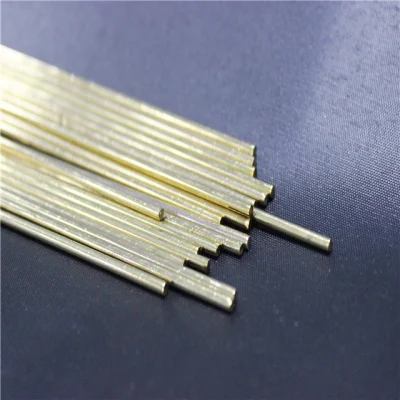

High Precision Clutch Bearing Sleeves Steel Die Casting Machining Parts

Package Size 10.00cm * 20.00cm * 30.00cm Package Gross Weight 2.000kg Products show Our production facilities show Our q

Send your inquiryDESCRIPTION

Basic Info.

| Model NO. | auto parts |

| Customized | Customized |

| Material | Stainless Steel |

| Transport Package | Carton, Pallet |

| Trademark | Bosswinn |

| Origin | China |

| Production Capacity | 24000 |

Packaging & Delivery

Package Size 10.00cm * 20.00cm * 30.00cm Package Gross Weight 2.000kgProduct Description

Products show

1.Materials we can process on | ||||

Stainless Steel | 201,304, 316, 416, 301,303, etc. | |||

Steel | Mild Steel, Carbon Steel, 4140, 4340, Q235, Q345B, 20#, 45#, etc. | |||

Brass | any standard or no standard brass | |||

Copper | C11000, C12000, C12200, C10100, etc. | |||

Iron | 20#, 45#, Q235, Q345, Q3458, 1214, 12L14, 1215, etc. | |||

| Aluminum | Al6061, Al6063, Al6082, Al7075, Al2024, Al5052, A380, etc. | |||

| 2. Products Surface Treatment | ||||

| Brushing, Polishing, Passivating, Laser cutting, painting, electroplating , blacken, Powder Coating, Sand blasting,Chemical Film, Brushing |

Our production facilities show

Our quality control facilities

Our company capabilites Technical Support Our engineers are skilled at AUTO CAD, PROENGINEER, SOLID, SketchUp. 3D max WORKS and other 2D & 3D software. We are able to design, develop, produce and deliver your PO according to your drawings, samples, or just an idea. control of non-standard products and OEM products.Quality Control1) Checking the raw material after they reach our factory------- Incoming quality control ( IQC) 2) Checking the details beforethe production line operated 3) Have a full inspection and routing inspection during mass production---In-process qualitycontrol(IPQC) 4) Checking the goods after they are finished---- Final quality control(FQC) 5) Checking the goods after they are finished-----Outgoing quality control(OQC)

Related Products

-

![Aluminum Based Master Alloy /Magnesium Master Alloy/Copper Master Alloy for Melting]()

Aluminum Based Master Alloy /Magnesium Master Alloy/Copper Master Alloy for Melting

-

![Silicon Bronze Copper Zinc Alloy Cuzn Brass Rod Brazing Alloy HS221]()

Silicon Bronze Copper Zinc Alloy Cuzn Brass Rod Brazing Alloy HS221

-

![New Material Liquid at Room Temperature Gallium Indium Tin Alloy Galinstan]()

New Material Liquid at Room Temperature Gallium Indium Tin Alloy Galinstan

-

![Wholesale Custom Powder Coated Anti Rust Welded Wrought Picket Boundary Corrugated Decorative Garrison/Security/Safety Fence for Metal/Carbon Steel/Iron]()

Wholesale Custom Powder Coated Anti Rust Welded Wrought Picket Boundary Corrugated Decorative Garrison/Security/Safety Fence for Metal/Carbon Steel/Iron